The Strangest Things That Were 3D-Printed in 2017

By Tereza Pultarova, Live Science, 18 December 2017.

By Tereza Pultarova, Live Science, 18 December 2017.

3D printing isn't new to 2017, but this year, researchers pushed the boundaries of the seemingly sci-fi technique, printing objects that required intricate details - such as a life-like model of a newborn and a microscopic camera - as well as objects made with materials that may sound surprising, including cheese and glass.

Read on for a roundup of the coolest and kookiest things that were 3D-printed in 2017.

1. A puppy mask

Photo credit: UC Davis Vet Med/YouTube

A 4-month-old Staffordshire bull terrier puppy became the first patient to use a new 3D-printed mask to help with recovery from serious facial injuries. The puppy's right cheekbone and jawbone, as well as her temporomandibular joint (the joint that connects the jawbone to the skull), were fractured when another dog attacked her.

The puppy, named Loca, was lucky it arrived at the University of California Davis School of Veterinary Medicine, where vets at the university had been cooperating with colleagues from the UC Davis College of Engineering on developing the "Exo-K9 Exoskeleton" mask for dogs. Loca was the ideal patient to test the technology on.

First, engineers scanned Loca's skull to design a custom-fit mask, which was then printed with a 3D printer. The mask held Loca's fractured face bones in place in the same way a cast holds fractured arm or leg bones. Within a month, the puppy could eat hard kibble, and a 3-month checkup showed that the temporomandibular joint was healing as expected.

2. Mouse ovaries

Photo credit: Northwestern University/YouTube

A female mouse fitted with 3D-printed ovaries gave birth to healthy pups in an experiment conducted at the Northwestern University Feinberg School of Medicine in Chicago.

The result was hailed as a breakthrough, as it may one day lead to new ways to treat infertility in humans, though much more research is needed. It could be particularly useful to women whose ovaries have been damaged because of cancer treatment, the researchers said.

Using the 3D-printing technology, the researchers created an elaborate porous scaffold made of gelatin. (Gelatin is a type of collagen, a natural protein found in the human body in large quantities.) The structure was then populated with ovarian cells from another mouse. The researchers tested various shapes of pores before landing on the particular shape that provided the right amount of support to the ovarian cells.

The experiment was a success: The implanted cells started behaving as cells in natural healthy ovaries would, eventually producing hormones that drive the mouse's reproduction cycle. and enabling it to get pregnant.

3. A residential house

Photo credit: Apis Cor

The first 3D-printed residential house was constructed in less then 24 hours in the suburbs of Moscow in March. The walls of the studio-like 400-square-foot (37 square meters) home were printed using a mobile construction 3D-printer developed by Moscow-headquartered startup Apis Cor.

Instead of printing individual concrete panels that would be later manually assembled, the 3D printer printed the walls and partitions as one fully connected structure, allowing for the house's unusual round shape.

The roof, doors and windows were the only components that had to be installed subsequently by human workers. The prototype house cost about US$10,134, or US$25 per square foot (US$275 per square meter). The most expensive components, according to the developers, were the windows and the doors.

The company believes that 3D printing could make construction not only considerably faster but also more eco-friendly.

4. House of glass

Glass, a material used by humankind since ancient Egypt, has long resisted 3D-printing. This is because, to be processed, the material needs to be heated to extremely high temperatures of up to 1,832 degrees Fahrenheit (1,000 degrees Celsius). Though complex industrial 3D-printers exist that can heat materials to very high temperatures using lasers, when used on glass, the resulting product was rather course and unusable.

Researchers from Germany's Karlsruhe Institute of Technology in Eggenstein-Leopoldshafen solved the problem with a new technique that enables creating complex glass structures with a conventional 3D printer - without the need of the laser heating.

As a starting material, the engineers used so-called liquid glass - a mixture of nanoparticles of silica, the material glass is made from - dispersed in an acrylic solution. An object is 3D-printed and then exposed to UV light, which hardens the material into a kind of plastic like acrylic glass. Then, the object is heated to about 2,372 degrees F (1,300 degrees C), burning away the plastic and fusing the silica nanoparticles together into a smooth, transparent glass structure.

5. Cheese

Photo credit: Erin McCarthy/YouTube

Unlike glass, cheese can be melted easily. So it's not a surprise that researchers saw the dairy product as an ideal candidate for 3D-printing experiments with food.

A team of researchers from the School of Food and Nutritional Sciences at University College Cork in Ireland used a mixture that's similar to the one used for making processed cheese and squirted it through a nozzle of a 3D printer to create a "new" kind of processed cheese.

The mixture was heated to 167 degrees Fahrenheit (75 degrees Celsius) for 12 minutes, and then run through the 3D printer at two different extrusion rates. (The extrusion rate is the speed at which the printer pushes the melted cheese out through the syringe.)

Processed cheese contains a mixture of ingredients, including emulsifiers, saturated vegetable oils, extra salt, food coloring, whey and sugar. It might not be exactly the healthiest type of cheese, so it's not clear whether the new treat would receive a nutritionist's seal of approval.

Still, from the researchers' perspective, the 3D-printed cheese was a success. It was 45 percent to 49 percent softer than untreated processed cheese, a little darker in color, a bit springier and more fluid when melted. The study didn't provide any conclusions on taste.

6. Life-like baby manikins

Photo credit: 3D Hubs

Babies that feel like real have been 3D-printed by Dutch researchers, who hope to improve training methods for doctors working with newborns.

The baby manikins that are currently used for doctors' training are too mechanical and don’t provide the real feel of treating a fragile infant, lead researcher Mark Thielen, a medical design engineer at the Eindhoven University of Technology in the Netherlands, told Live Science in March.

3D-printing enabled Thielen and his team to create anatomically accurate manikins that include realistic internal organs. To achieve the highest level of accuracy, the researchers used MRI scans of newborns' organs that were subsequently printed out with a high level of detail. For example, a 3D-printed heart would include detailed, working valves. The manikins even have blood-like fluid circulating in their veins.

The aim is to provide a high level of realistic tactile feedback when performing clinical interventions on manikins, Thielen said. In other words, when the surgeons move a part of the manikin or apply pressure to a certain area, it feels and moves like the real thing.

7. Eyes

3D-printed eyes have been created by Dutch researchers that can help children born without properly developed eyes look relatively normal. Unfortunately, the 3D-printed eye prostheses won't give the children the ability to see.

About 30 in every 100,000 children are born with conditions called microphthalmia and anophthalmia, which means that their eyes are either completely missing or underdeveloped. As a result, their eye sockets lack the structural support they need for the children's faces to develop in a normal way.

If an adult loses an eye, they will be given permanent eye prosthesis. This is not possible in children, however, who grow very fast, especially in the first months and years of their lives.

3D-printing of temporary supportive structures, called conformers, can be done quickly, cheaply and in a range of very precise sizes, the researchers said.

This is extremely important as, without the eye, the bone around the socket lacks proper stimulation and the face doesn't develop natural-looking proportions.

The conformers have already been tested on a small group of five children as of May.

8. A rock-climbing robot

Photo credit: Jacobs School News, UC San Diego/YouTube

A robot with soft rubbery 3D-printed legs demonstrated its superb abilities to conquer rough terrain, a task that usually paralyzes traditional robots.

Engineers from University of California, San Diego, digitally designed the robot's legs and modeled its performance and behavior in various situations - for example, on a soft, sandy surface, in narrow spaces or when climbing over rocks.

They eventually chose a design that consisted of three connected spiral-like tubes that are hollow inside and made from a combination of soft and rigid materials.

As they are taking a step, the legs test out the surrounding terrain and then adjust instantaneously, through pistons that inflate in a certain order and determine the robot's gait.

The novelty of the design, according to the engineers, is the fact that the robot's legs can bend in all possible directions.

9. "Laughter"

Photo credit: NASA via Space.com

The first-ever piece of art was created in space in February this year using a 3D printer aboard the International Space Station.

The piece of art represents human laughter, and was created in a collaboration between Israeli artist Eyal Gever and the California-based company Made In Space as part of the project called #Laugh.

Space enthusiasts were invited to participate in the creation of the piece of space art via an app that captures users' laughter and turns it into a digital 3D-model resembling a star.

More then 100,000 people contributed their laughter to the project, which started in December 2016. The app users then chose the best laugh star, which was based on the laughter of Naughtia Jane Stanko of Las Vegas. The design was subsequently beamed to the ISS and 3D-printed on a machine that is usually used for making spare parts.

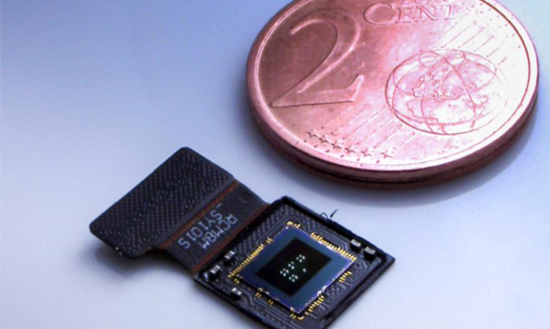

10. Micro-camera

Photo credit: Simon Thiele via Live Science

A micro-camera that could be used on miniature drones and robots or surgical endoscopes was created by German researchers with the help of 3D printing.

The camera provides eagle-eye vision - the ability to see faraway objects clearly while at the same time being aware of what's going on in peripheral vision.

To create the device, engineers from the Institute of Technical Optics at the University of Stuttgart in Germany printed clusters of four lenses onto an image-sensing chip using a technique called femtosecond laser writing.

The miniature lenses range from wide to narrow and from low- to high-resolution. This structure enables images to be combined into a bull’s-eye shape with a sharp image at the center, similar to how eagles see.

The four lenses can be scaled down to as small as 300 micrometers by 300 micrometers (0.012 inches, or 0.03 centimeters, on each side), about the size of a grain of sand. But the researchers say they might be able to make the device even smaller in the future when smaller chips become available.

No comments:

Post a Comment

Please adhere to proper blog etiquette when posting your comments. This blog owner will exercise his absolution discretion in allowing or rejecting any comments that are deemed seditious, defamatory, libelous, racist, vulgar, insulting, and other remarks that exhibit similar characteristics. If you insist on using anonymous comments, please write your name or other IDs at the end of your message.