Ten Technologies That Will Revolutionize Car Manufacturing

By Chris Perkins, Jalopnik, 24 September 2014.

By Chris Perkins, Jalopnik, 24 September 2014.

Car manufacturing is rapidly changing and these are the technologies that are driving that change.

10. Wearables

Photo credit: Jason Torchinsky/Jalopnik

Ok so, as of right now, things like Google Glass and the Apple Watch are mostly just the butt of jokes but they could have some really useful applications in the automotive world, as Jason explored.

Anyone working on a car, like someone on an assembly line or you in your garage with your old Beetle, could have a world of information right before your eyes. (Suggested By: Chris_K_F)

9. Solar

Solar technology is rapidly becoming price competitive with conventional energy sources and this will have a huge impact on both the manufacturing and possibly propulsion of cars. Cars and factories could potentially be much greener. (Suggested By: Ash78, Rock the Slushbox/davedave1111)

8. Camless Engines

Photo Credit: GF Williams/Jalopnik

Internal combustion engines have had camshafts since, well, the dawn of internal combustion. The nuts over at Koenigsegg have developed one that uses pneumatic actuators to open and close the valves. Read our man Travis' report and be amazed. (Suggested By: austin webb)

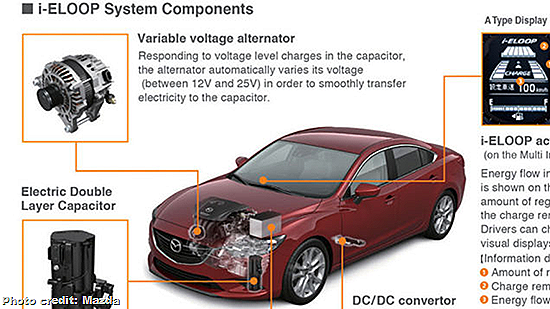

7. Energy Storage

Here's an example of a race car technology that is slowly filtering its way down to road cars. Not only do you see capacitor systems like KERS in hypercars like LaFerrari, but in more plebeian cars like a Mazda with its i-ELOOP system. (Suggested By: DennyCraneDennyCraneDennyCrane)

6. Just-In-Time Sales Model

Reader nermal thinks that a big change in manufacturing will come from a change in the sales model.

"The majority of modern manufacturing has shifted to a "Just In Time" supply model, where inventories of raw materials are kept to a minimum. As a result, overhead and materials waste are lowered because the raw materials ordered are only just the amount needed when they're needed. This concept can then be moved on to the sales floor.

Building a new auto can take place in as little as a day.

As a result of that, it's not inconceivable to have a delivery timeline of as short as a week. A custom order is placed on Monday, your car is built on Tuesday, and it takes 3 days or so to ship to your dealer, then you pick it up the following week at your leisure.

What will this do to the manufacturing side? It will require manufacturers to be much more nimble with supply and production changes to react to market demands. Production lines will need to be made more modular. Think VW's MQB platform - You could see a GTI followed by a Jetta followed by 3 Tiguans on the same production line, because so much of the core platform is shared and modular. At the same time, doing so will increase profitability by eliminating the need to add heavy incentives to slow selling models that sit on dealer lots for too long.

Moving to this model will also give an enormous incentive to move manufacturing to the US, since the longest portion of the production cycle will be the transport piece."

5. Vehicle Automation

Obviously widespread adoption of autonomous cars is more than a few years away, but their existence has huge implications for car design. Since they theoretically would mitigate most potential accidents, the need for additional safety features would be reduced. Why need heavy crash structures, airbags and the rest in a car that never crashes? (Suggested By: abcs)

4. The Gigafactory

Elon Musk wants his gigantic new Gigafactory to supply batteries for 500,000 cars by 2020 which means that battery technology will be able to be spread around to more manufactures than Tesla. This will be huge in the mainstreaming of electric cars. (Suggested By: Titan-E34)

3. Electric Propulsion

As the McLaren P1, Porsche 918, and LaFerrari have proven this is a future not to be feared but embraced. Electric propulsion can give huge gains in both performance and efficiency.

Who said you can't have your cake and eat it too? (Suggested By: McSeanerson)

2. Modular Chassis

Volkswagen is leading the way in modular chassis technology with its scalable MQB platform which underpins the Audi A3, the new TT, the Mk7 VW Golf, the Seat Leon, and the Skoda Octavia.

Expect to see many manufactures going forward with this sort of approach in the not too distant future, allowing automakers to develop a host of products on one platform while keeping costs low. (Suggested By: POD)

1. Carbon Fibre/Composite Materials

The phrase "simplify, then add lightness," attributed to Lotus mastermind Colin Chapman is one that is bandied about quite a bit here at Jalopnik but there is a lot of truth to it. To make cars lighter is to make them faster and more fuel efficient, which satisfies everyone from the governments to the enthusiasts.

Carbon fibre has gone from race cars and exotic sports cars, to now slowly making its way into the mainstream. BMW has invested heavily in it for its i3 and i8 so expect to see it used more and more. (Suggested By: In a Mini; let them mock me as My Mini Countryman is higher than you)

No comments:

Post a Comment

Please adhere to proper blog etiquette when posting your comments. This blog owner will exercise his absolution discretion in allowing or rejecting any comments that are deemed seditious, defamatory, libelous, racist, vulgar, insulting, and other remarks that exhibit similar characteristics. If you insist on using anonymous comments, please write your name or other IDs at the end of your message.